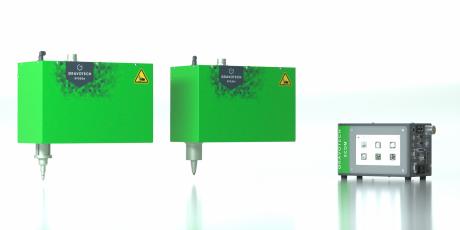

XF530 p/m

Electromagnetic & pneumatic

200 x 50 mm (7.9 x 2'')

Plastics and metals

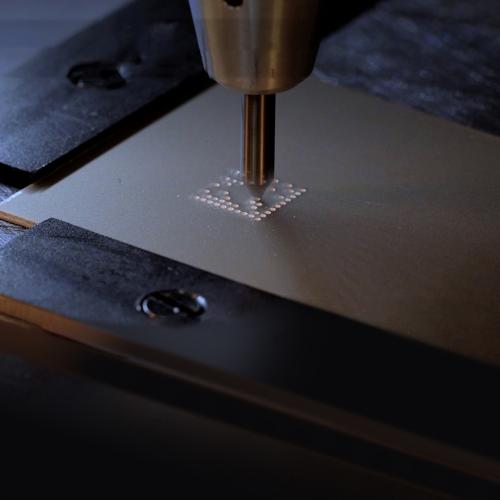

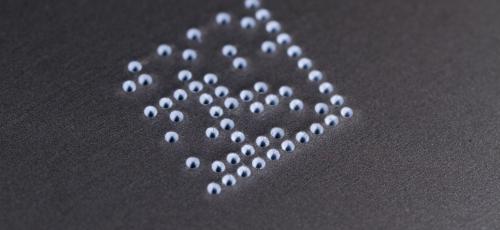

- DEEP MARKING

With up to 0.5 mm depth, the XF530 dot peen machine is the only deep marking system able to reach this level of depth in such a short cycle time. The marking results are clear and resistant to weather conditions, contaminants, rust, and guaranteed long-term readability. Its also the best solution to perform a direct marking before part processing, painting, or surface treatment.

- DOT PEEN ENGRAVING

The XF530 large marking area of 200 mm (7.9 in) X 50 mm (2 in) is specially adapted to engrave large characters (more than 10mm (0.4) height) for easy readability from a long distance or in outdoor locations. This deep dot peen marking machine is the perfect solution for the oil & gas market and building industries.

- DEEP ENGRAVING MACHINE

This deep dot peen engraving machine in pneumatic or electromagnetic version is made of high-quality and high-performance components. Its proven design has been improved for decades to obtain exceptional durability and reliability, especially in the most demanding applications. XF530 is guaranteed to have durable tamper-proof marks on all materials with a reduced cost of ownership.

Discover the XCOM, the connected touch screen controller which drive your XF530.