Our interchangeable cutting tables allow you to choose the most suitable support for your application.

Laser cutting bed: A cutting support to meet your requirements

- CUTTING QUALITY

Depending on your projects and the materials used, it is essential to adapt the work surface of your laser engraving machine in order to have an optimal result. Our cutting supports are necessary to guarantee the preservation of the material during your projects, during laser engraving, laser cutting or laser marking.

- IMPROVED AIR EXTRACTION

For all our cutting support solutions in our laser cutting machines, the risk of burn marks is eliminated thanks to the high extraction power which offers a fast elimination of the vapors from the marked, engraved or laser cut materials.

- PRECISE AND STABLE POSITIONING

The supports, which are fully adjusted to your laser cutter work table, also have distinct characteristics. It is necessary that the material rests on a few points so that the laser beam can pass through the material and allow the fumes caused by the laser to be evacuated by the table's suction.

Technical specifications

In order to obtain the best possible cutting quality, it is necessary to:

- Limit the contact points between the part to be cut and the cutting table as much as possible.

When the laser beam passes over a contact point, it may reflect and create an impact point on the back of the part.

- Optimize the airflow to remove dust and fumes as much as possible.

A build-up of dust and smoke can create a flashover that can blacken the cut.

In addition, this build-up will result in a rapid clogging of the optics, which will cause an immediate loss of power.

General

Honeycomb cutting table

Laser cutter honeycomb tables provide more stability for the material because thanks to the multiple support points. They are ideal for thin products or consumable sheets. With a large surface area covering the entire engraving area, the laser cutter honeycomb support is suitable for single or mass engraving. The hollow grid shape allows the laser beam to pass through the material while evacuating the vapors in an optimal way. These laser cutter mounts are ideal for combining engraving and cutting work.

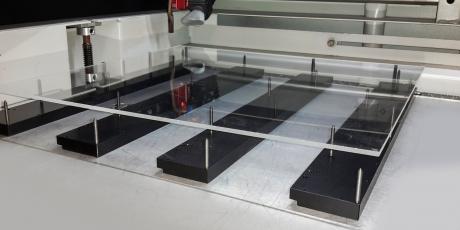

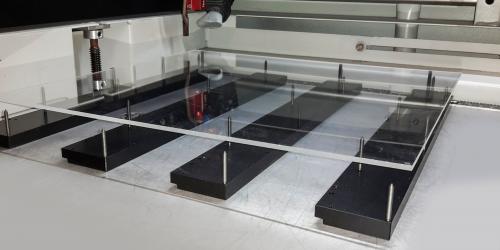

Pin table for laser cutter

For delicate materials, such as acrylic, the support should minimize back-flashes to avoid reflection marks. For this type of work, we recommend our pin table for laser cutters. With this modular support, you can arrange the supporting elements (pins and layout) yourself so that it perfectly meets the needs of your project. This cutting table is particularly suitable for the creation of parts intended for the realization of models or model making.

● Reduced backflash effect

● Quick and easy assembly

● Removable pins

● Suitable for XY laser cutting machines

Laser cutting slats

Our laser cutting slats ensures a low number of contact points with the workpiece, and is covered with a black anodized coating to prevent discoloration of the underside of the material due to laser back-flash.

This laser cutting support is suitable for rigid and bulky materials.

The cut parts and scraps fall into a collecting tray and can easily be recovered at the end of the engraving process.

Using the various slots in the machine, add or remove blades depending on the size of the part.

The slats are positioned in the machine at a 6° angle to avoid a straight cut following a blade.

- Easy to install

- Adaptable to any part size

- Easy ventilation of fumes and particles

- Waste collection tray for scraps

- Compatible only with our LS1000 XP laser cutting machine

Associated Products

Small CO2 laser engraver and cutter for personalization, signage and creative.

LS100

Medium CO2 or Fiber laser engraving and cutting machine for signage and small series.

LS100EX

Large laser engraver and cutter that can do everything.

LS900

LS1000XP

Laser tables lenses

Laser exhaust system

Laser nozzle

3D Stylus

High frequency spindles

Bevelling machines

Chip collector

The eZ Laser axis provides adjustable height to your laser marking head. Mark parts of various sizes by adjusting the Z axis height of the plateau, holding the integrable marking machine.

eZ Laser axis

Connect up to four pneumatic dot-peen or scribing marking heads to one XCOM with this accessory.