FIBER Laser

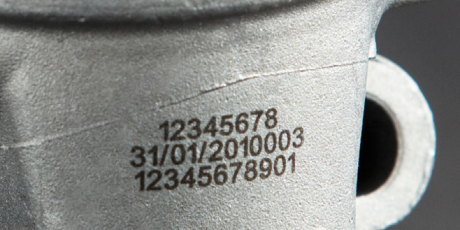

- COMPACT DEEP LASER ENGRAVING

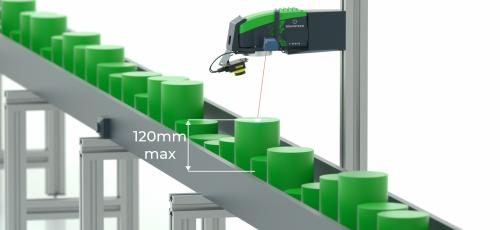

The heavy-duty design, based on a cast aluminum structure, and high-quality optical components guarantee strength and low maintenance. Whether integrated in a production lines or robotic cell. The integrated laser implementation is easy in all mounting positions, the laser can be oriented to the part surface to significantly reduce installation times and tooling costs.

- INDUSTRIAL LASER

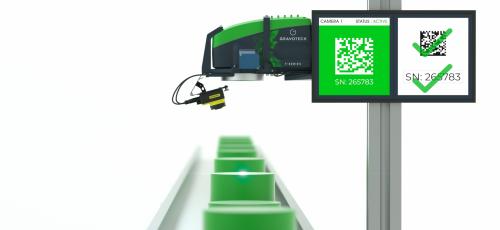

Equipped to meet the needs of Industry 4.0, the fiber laser engraver for metal, can use many network and fieldbus protocols allowing full compatibility with all PLCs brands to ensure quick and cost-effective integration.

- POWERFUL FIBER LASER MARKER

This deep laser marking machine is available in several powers; 20W, 30W and 50W. 20W is adapted for most applications for surface marking, 30W is the solution for fast and high-contrast markings, and 50W is the most suitable solution for deep laser engraving.

Looking for a simple & affordable laser marker? The Fiber ENERGY contains all core features necessary for basic applications.

Ready to purchase? Visit Gravotech Markit to purchase all Gravotech machines.