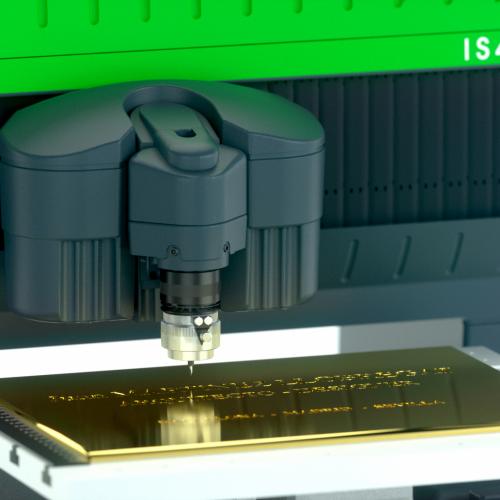

With more than 10,000 units sold, the IS400 is a stable, safe, versatile, CNC engraving machine. Since the nineties, most of the IS400s' sold are still running in all types of industries, used as a sign engraver, plastic engraving machine, metal cutting, and as a great ADA braille engraving machine. The IS400 rotary engraving machine can also be split from its base, so it can be attached to a customized support. You are free to define your own engraving axis, tilt angle, automation to work at a competitive cost on rail or aviation components, wind turbine blades, etc.